Annotation

- Introduction

- Understanding Flux Copilot's AI-Driven Approach

- Core Functionality and Design Modules

- Practical Implementation Guide

- Pros and Cons

- Industry Applications and Real-World Impact

- Conclusion

- Frequently Asked Questions

Flux Copilot Review: AI-Powered Electronics Design Platform for Faster Hardware Development

Flux Copilot leverages artificial intelligence to streamline electronics design, automating tasks from architecture planning to PCB layout, reducing

Introduction

Flux Copilot represents a significant advancement in electronic design automation, leveraging artificial intelligence to transform how engineers and designers approach hardware creation. This comprehensive platform streamlines the entire design workflow from initial concept to manufacturing-ready output, reducing traditional barriers and accelerating innovation across multiple industries including consumer electronics, automotive, and aerospace sectors.

Understanding Flux Copilot's AI-Driven Approach

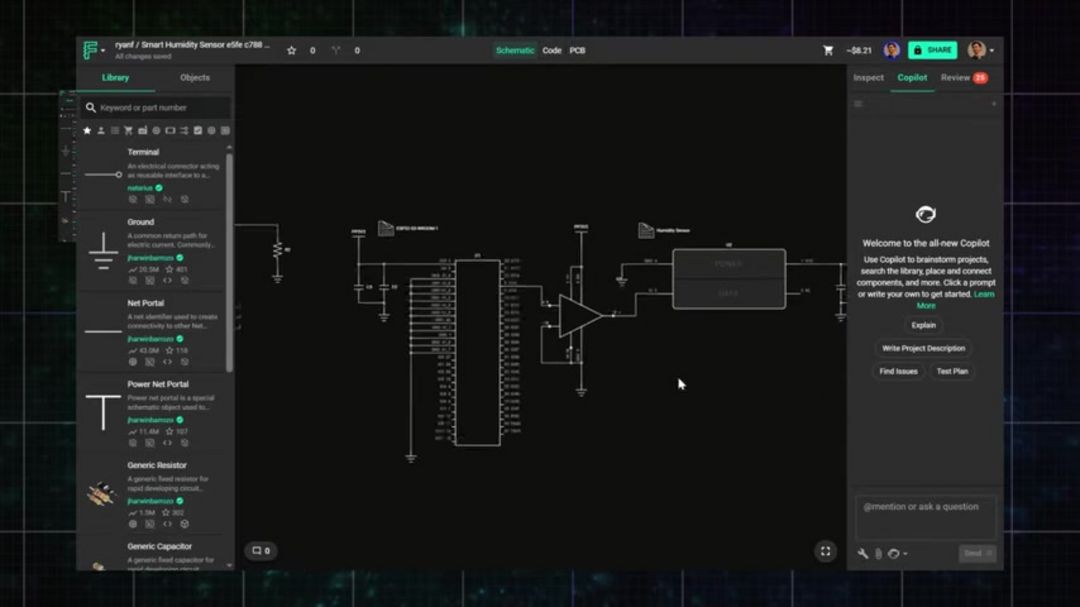

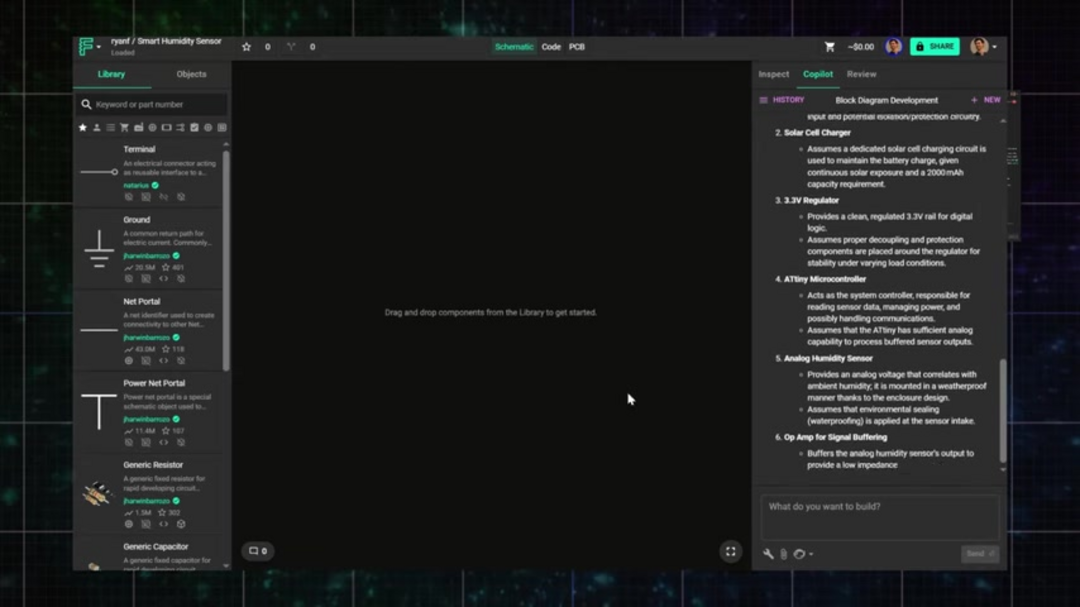

Flux Copilot functions as an intelligent design assistant that interprets natural language inputs to generate electronic hardware designs. Unlike traditional electronic design automation tools that require extensive technical expertise, Copilot allows users to describe their requirements in plain English, which the AI then translates into actionable design specifications. This approach significantly lowers the learning curve while maintaining professional-grade output quality.

The platform's core innovation lies in its ability to understand design intent and context. When you specify requirements for a project – whether it's a simple sensor circuit or complex IoT device – the AI analyzes your input against industry standards, component availability, and manufacturing constraints to propose optimal solutions. This contextual understanding helps prevent common design pitfalls that often emerge later in the development cycle.

What sets Flux Copilot apart from conventional design software is its collaborative nature. The platform treats the AI as a virtual team member that can brainstorm ideas, suggest alternatives, and document design decisions. This collaborative approach is particularly valuable for distributed teams working across different time zones, as it maintains design consistency and ensures all stakeholders remain aligned throughout the development process.

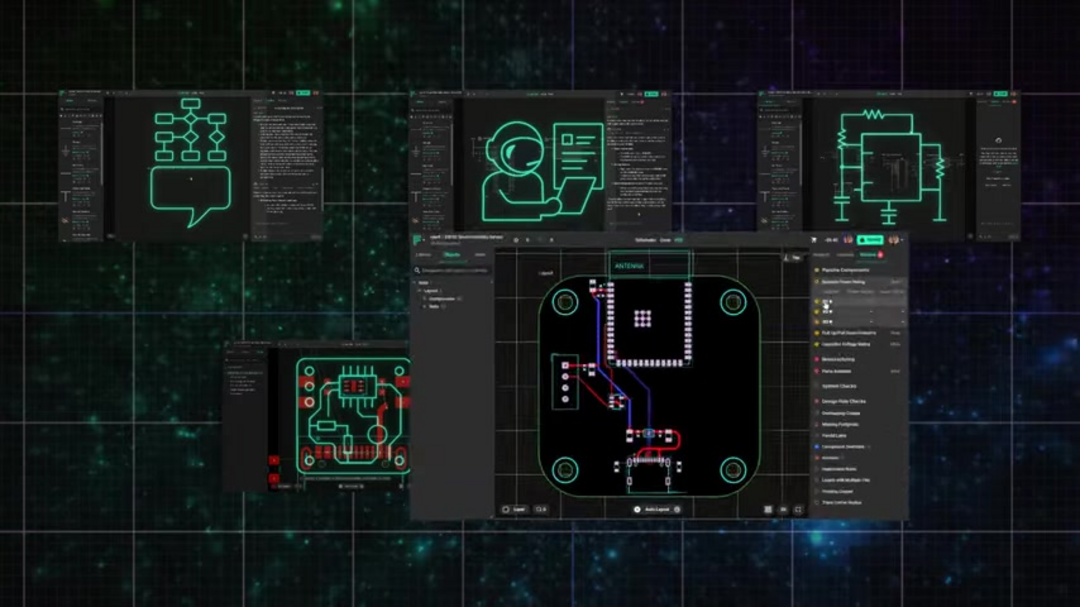

Core Functionality and Design Modules

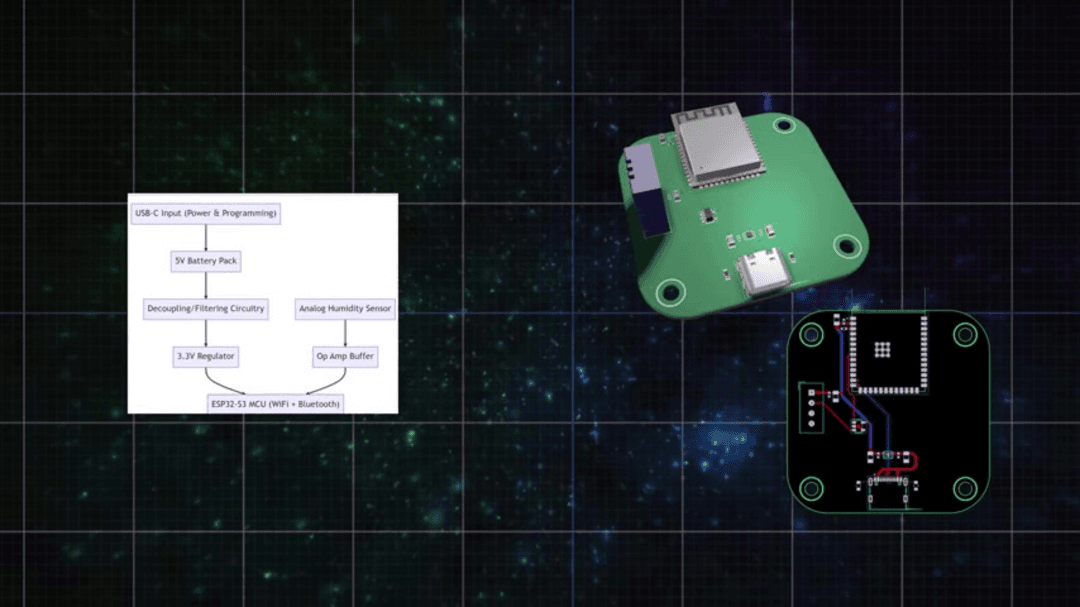

Architecture Planning with Intelligent Assistance

During the architecture phase, Flux Copilot acts as a strategic partner in defining your project's foundation. The AI helps translate high-level requirements into detailed technical specifications by generating comprehensive block diagrams and system architectures. For instance, if you're designing a smart home device, Copilot can suggest appropriate communication protocols, power management strategies, and sensor integration approaches based on your specific use case.

The system documents all AI-generated assumptions and design choices, allowing engineers to review and modify them as needed. This transparency ensures that the final architecture aligns perfectly with project objectives while leveraging the AI's extensive knowledge of industry best practices and emerging technologies in the circuit design space.

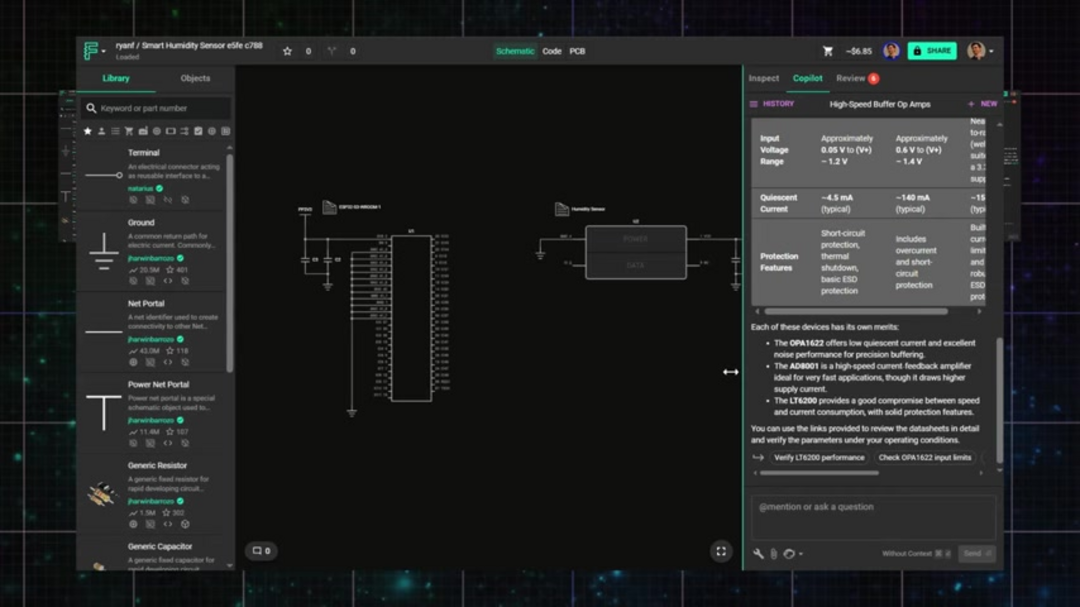

Intelligent Component Research and Selection

Component selection becomes dramatically more efficient with Flux Copilot's AI-driven research capabilities. The platform accesses extensive component databases to provide real-time recommendations based on performance requirements, cost constraints, and availability. When researching components for a specific function, Copilot presents comparative analyses that highlight trade-offs between different options – such as power consumption versus processing speed or cost versus reliability.

The AI considers factors that human designers might overlook, such as component lifecycle status, alternative sourcing options, and potential supply chain disruptions. This comprehensive approach to component selection helps prevent costly redesigns later in the process and ensures your design remains manufacturable throughout its expected production lifespan.

Automated Schematic Capture and Integration

Flux Copilot revolutionizes schematic creation by automatically extracting component values, calculating parameters, and integrating datasheet information directly into your design. This automation eliminates the tedious manual data entry that typically consumes significant engineering time while reducing the risk of transcription errors that can compromise design integrity.

The platform's intelligent schematic capture goes beyond simple connectivity by understanding functional relationships between components. For example, when you add a microcontroller, Copilot automatically suggests appropriate decoupling capacitors, crystal oscillators, and programming interfaces based on the selected device's requirements and your overall system architecture.

PCB Layout and Routing Automation

PCB layout represents one of the most time-intensive aspects of electronic design, and Flux Copilot addresses this challenge with sophisticated automation capabilities. The platform's auto-layout function considers multiple factors simultaneously – including signal integrity, thermal management, manufacturability, and electromagnetic compatibility – to generate optimized board layouts.

Designers can start with manual component placement for critical sections, then leverage Copilot's routing intelligence to handle the remaining connections. The AI understands design intent from your schematic annotations and component placements, ensuring that high-speed signals receive appropriate routing priority while power distribution networks are optimized for efficiency. This approach is particularly valuable for teams working on complex PCB design projects with tight deadlines.

Design Verification and Manufacturing Preparation

The final review stage benefits significantly from Flux Copilot's AI-driven verification capabilities. The platform performs comprehensive design rule checks that go beyond basic spacing and clearance requirements to include manufacturing-specific constraints, testability considerations, and assembly requirements. This proactive approach identifies potential issues before they become costly manufacturing problems.

Copilot's verification system also includes component availability checks, ensuring that your design doesn't rely on obsolete or hard-to-source parts. The AI suggests alternatives when components face supply chain challenges, and it can optimize your bill of materials for cost efficiency without compromising performance. This level of preparation is essential for successful AI automation platforms integration into production workflows.

Practical Implementation Guide

Getting Started with Your First Project

Initiating a project in Flux Copilot begins with clearly defining your objectives using natural language. Be specific about performance requirements, environmental conditions, cost targets, and timeline constraints. The more detailed your initial input, the more accurately the AI can assist throughout the design process. For example, instead of simply requesting "a temperature sensor," specify the measurement range, accuracy requirements, power constraints, and communication interface needs.

Leveraging AI Throughout the Design Cycle

As you progress through each design phase, consistently engage Copilot for recommendations and validations. During architecture development, use the AI to explore alternative approaches you might not have considered. In component selection, leverage its comparative analysis capabilities to make informed trade-off decisions. During schematic capture and PCB layout, trust the automation for routine tasks while focusing your expertise on critical design elements that require human judgment.

Collaboration and Iteration Strategies

Flux Copilot excels in collaborative environments where multiple stakeholders contribute to the design process. Use the platform's version control and commenting features to track design decisions and facilitate team discussions. The AI maintains context across iterations, helping ensure that design changes in one area don't inadvertently create problems elsewhere. This collaborative approach is particularly valuable when working with distributed teams or external partners using various AI APIs and SDKs for integration.

Pros and Cons

Advantages

- Accelerates design process by automating routine tasks

- Reduces learning curve with natural language interface

- Enhances collaboration across distributed design teams

- Improves design quality with AI-driven verification

- Optimizes manufacturability through comprehensive DRC

- Provides real-time component availability and pricing

- Democratizes access to advanced electronics design

Disadvantages

- Initial adaptation period for traditional EDA users

- Dependency on AI algorithms for critical decisions

- Potential limitations for highly specialized applications

- Subscription costs may deter individual hobbyists

- Requires reliable internet connection for full functionality

Industry Applications and Real-World Impact

Flux Copilot demonstrates significant value across multiple industries where electronic design plays a crucial role. In consumer electronics, the platform accelerates development of IoT devices, wearables, and smart home products by streamlining the transition from concept to manufacturable design. Automotive engineers benefit from Copilot's ability to manage complex system integrations while ensuring compliance with industry standards.

Healthcare applications particularly benefit from the platform's emphasis on reliability and precision. Medical device developers can leverage the AI's verification capabilities to ensure their designs meet stringent regulatory requirements while optimizing for manufacturability and cost efficiency. Similarly, industrial automation projects gain from Copilot's ability to handle complex control systems and communication interfaces that are essential in modern manufacturing environments.

The platform's collaborative features make it particularly valuable for research and development teams working on cutting-edge technologies. By facilitating knowledge sharing and maintaining design consistency, Flux Copilot helps accelerate innovation while reducing the risk of errors that can delay project timelines. This makes it an excellent choice for organizations exploring new applications of AI agents and assistants in their products.

Conclusion

Flux Copilot represents a paradigm shift in electronic design, bridging AI and practical hardware development. It combines natural language processing with design automation to make professional electronics design accessible and enhance productivity. The platform ensures designs are optimized for performance, cost, and manufacturability from conception to production, becoming essential for innovation across industries.

Frequently Asked Questions

What types of electronic designs can I create with Flux Copilot?

Flux Copilot supports diverse electronic designs from simple sensor circuits to complex IoT devices, automotive systems, and aerospace components using natural language input and AI-driven design assistance.

Is Flux Copilot suitable for beginners in electronics design?

Yes, the natural language interface and AI guidance make Flux Copilot accessible for beginners while providing advanced features that professional engineers need for complex projects.

How does Flux Copilot ensure designs are manufacturable?

Flux Copilot incorporates comprehensive design rule checks, AI-driven reviews, and component availability verification to ensure designs meet industry standards and manufacturing constraints from the beginning.

Does Flux Copilot integrate with other design tools?

Currently operating within its ecosystem, though future updates may include integrations with popular design tools. Check official documentation for latest supported integrations.

What is the pricing model for Flux Copilot?

Flux Copilot offers subscription-based pricing with tiers for individuals, teams, and enterprises. Visit the official website for detailed plans and costs.

Relevant AI & Tech Trends articles

Stay up-to-date with the latest insights, tools, and innovations shaping the future of AI and technology.

Grok AI: Free Unlimited Video Generation from Text & Images | 2024 Guide

Grok AI offers free unlimited video generation from text and images, making professional video creation accessible to everyone without editing skills.

Top 3 Free AI Coding Extensions for VS Code 2025 - Boost Productivity

Discover the best free AI coding agent extensions for Visual Studio Code in 2025, including Gemini Code Assist, Tabnine, and Cline, to enhance your

Grok 4 Fast Janitor AI Setup: Complete Unfiltered Roleplay Guide

Step-by-step guide to configuring Grok 4 Fast on Janitor AI for unrestricted roleplay, including API setup, privacy settings, and optimization tips