Annotation

- Introduction

- AI Applications in Manufacturing with EOS

- Introduction to AI in EOS Systems

- Anomaly Detection Using Sensor Data

- Image Recognition in Manufacturing Processes

- Knowledge Management Tools and AI Integration

- Advanced Techniques and AI Integration

- OT Camera Integration

- How to Utilize AI Features in EOS Systems

- Step-by-Step Guide to Implementing AI in Manufacturing

- Pros and Cons

- Conclusion

- Frequently Asked Questions

AI in Manufacturing: EOS Systems Revolutionizing Production with Smart Technology

Discover how EOS systems use AI for advanced anomaly detection, image recognition, and knowledge management to revolutionize manufacturing processes,

Introduction

Artificial intelligence is fundamentally reshaping manufacturing landscapes, and EOS systems stand at the forefront of this technological revolution. By integrating sophisticated AI capabilities into additive manufacturing processes, EOS enables unprecedented levels of precision, efficiency, and quality control. This comprehensive exploration examines how AI applications within EOS systems are transforming traditional manufacturing workflows through advanced anomaly detection, intelligent image recognition, and enhanced knowledge management solutions that collectively drive innovation across industrial sectors.

AI Applications in Manufacturing with EOS

Introduction to AI in EOS Systems

The integration of artificial intelligence into EOS manufacturing platforms represents a significant leap forward in industrial automation and process optimization. These advanced systems leverage machine learning algorithms to analyze vast datasets generated by multiple sensors, enabling real-time adjustments and predictive capabilities that were previously impossible. The synergy between AI and EOS technologies creates a manufacturing environment where machines continuously learn from operational data, anticipate potential issues, and autonomously optimize performance parameters.

This technological convergence addresses critical manufacturing challenges while opening new possibilities for innovation. For manufacturers exploring AI automation platforms, EOS systems demonstrate how intelligent algorithms can transform traditional production methods into adaptive, data-driven processes that consistently deliver superior results while reducing operational costs and material waste.

The core advantage of AI integration lies in its ability to process complex information patterns that human operators might miss. By continuously monitoring hundreds of variables simultaneously, EOS systems with AI capabilities can identify subtle correlations between process parameters and final product quality, enabling manufacturers to achieve unprecedented consistency and reliability in their additive manufacturing operations.

Anomaly Detection Using Sensor Data

Anomaly detection represents one of the most valuable AI applications in EOS systems, utilizing sophisticated machine learning models to identify deviations from established operational patterns. EOS manufacturing equipment incorporates numerous high-precision sensors that continuously monitor critical parameters including temperature gradients, pressure variations, vibration frequencies, and laser power stability. These sensors generate massive datasets that AI algorithms analyze in real-time to detect even minute anomalies that could indicate emerging issues.

The implementation process involves training machine learning models on extensive historical data representing both optimal and suboptimal manufacturing conditions. Through this training, the AI develops a comprehensive understanding of normal operational ranges and can immediately flag any parameter deviations that fall outside acceptable thresholds. This capability is particularly crucial in additive manufacturing, where subtle variations in environmental conditions or material properties can significantly impact the structural integrity and dimensional accuracy of finished components.

For companies implementing sensor monitoring solutions, EOS demonstrates how comprehensive data collection combined with intelligent analysis can transform maintenance strategies from reactive to predictive approaches. The system's ability to identify patterns preceding equipment failure allows manufacturers to schedule maintenance during planned downtime rather than experiencing unexpected production interruptions.

Practical applications of anomaly detection include identifying unusual thermal patterns within build chambers that might indicate heating element degradation, detecting vibration signatures suggesting mechanical wear in motion systems, and flagging pressure inconsistencies that could signal material feed problems. By addressing these issues proactively, manufacturers can maintain consistent product quality while minimizing scrap rates and optimizing material usage.

Image Recognition in Manufacturing Processes

Computer vision and image recognition technologies have emerged as transformative AI applications within EOS manufacturing systems. These capabilities enable machines to visually inspect manufacturing processes with a level of consistency and precision that surpasses human capabilities. By training deep learning algorithms on extensive image datasets, EOS systems can automatically identify critical visual features, detect microscopic defects, and monitor process evolution throughout the entire manufacturing cycle.

The implementation of AI image recognition in manufacturing encompasses several critical functions: automated defect detection that identifies surface imperfections, cracks, or dimensional inaccuracies; quality inspection systems that verify component conformity to design specifications; real-time process monitoring that tracks printing progression against expected parameters; and automated sorting mechanisms that categorize components based on visual characteristics.

What makes this technology particularly powerful is its ability to perform these tasks continuously without fatigue or inconsistency. While human inspectors might miss subtle visual cues during extended monitoring sessions, AI-powered vision systems maintain constant vigilance, identifying even minute deviations that could indicate process drift or equipment calibration issues. This capability becomes increasingly valuable as manufacturing tolerances tighten and quality requirements become more stringent.

EOS printers equipped with advanced imaging systems capture high-resolution photographs throughout the manufacturing process, creating a comprehensive visual record that AI algorithms analyze to understand how the printing evolution correlates with final product quality. This data-rich approach enables manufacturers to identify optimal process parameters and establish visual benchmarks for successful production runs.

Knowledge Management Tools and AI Integration

Knowledge management represents a frequently overlooked but critically important application of AI within manufacturing environments. EOS systems leverage artificial intelligence to capture, organize, and disseminate organizational knowledge, transforming how manufacturing teams access information, solve problems, and maintain procedural consistency. This approach addresses the significant challenge of preserving institutional knowledge as experienced personnel retire or transition to new roles.

AI-enhanced knowledge management systems within EOS platforms provide several distinct advantages over traditional documentation approaches. Intelligent search capabilities enable engineers to quickly locate specific procedural information, technical specifications, or troubleshooting guides without manually sifting through extensive documentation archives. Natural language processing allows users to query the system using conversational language rather than requiring precise keyword matching.

For organizations implementing AI knowledge management solutions, EOS demonstrates how machine learning can automate information categorization, extract key insights from technical documents, and identify relationships between different knowledge domains. The system can automatically generate summaries of lengthy technical manuals, highlight critical safety considerations, and suggest relevant procedures based on current manufacturing contexts.

EOS has developed specialized AI interfaces, including chatbot functionality, that help manage version control across different system configurations and documentation revisions. This capability is particularly valuable for manufacturers operating multiple EOS systems with different software versions or hardware configurations. The AI system can instantly identify which procedures apply to specific machine variants, reducing configuration errors and ensuring consistent operation across the manufacturing floor.

Advanced Techniques and AI Integration

OT Camera Integration

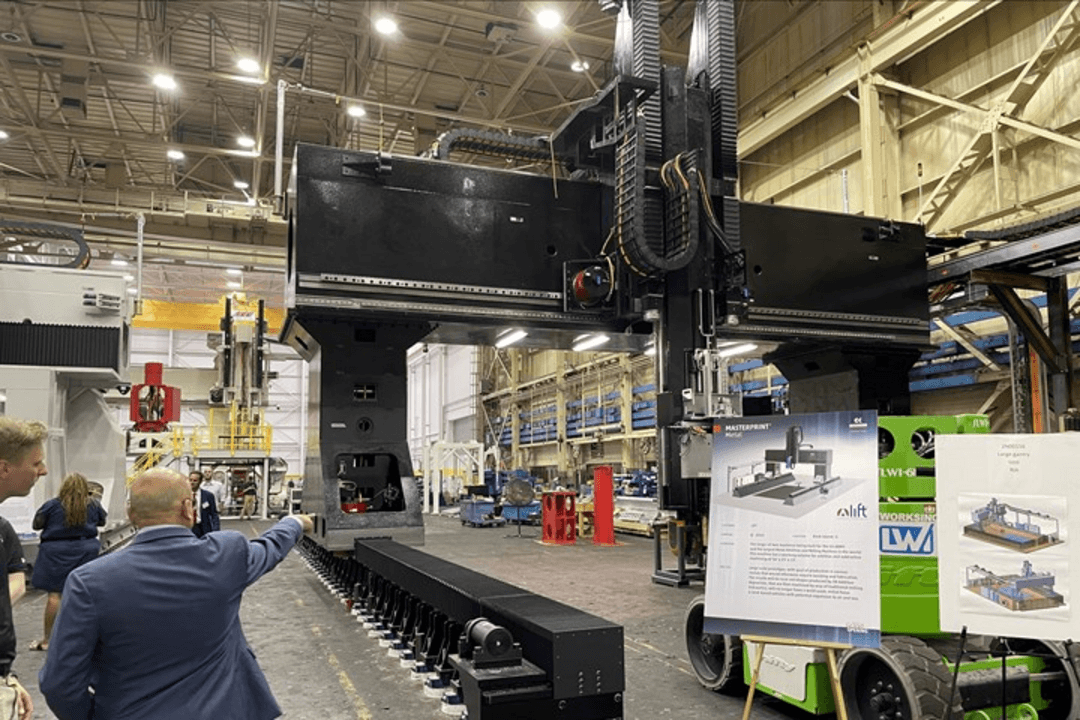

EOS systems incorporate specialized optical tomography (OT) cameras that capture specific wavelength emissions from the manufacturing process bed surface during printing operations. These advanced imaging systems build layer-by-layer visual records that create comprehensive datasets for AI analysis. The integration of OT camera technology with machine learning algorithms enables real-time process adjustments based on visual feedback, representing a significant advancement in closed-loop control for additive manufacturing.

The OT system's ability to detect thermal patterns and energy distribution across the build platform allows AI algorithms to identify areas receiving insufficient or excessive energy input. When the system detects these conditions, it can automatically adjust laser parameters to compensate, ensuring consistent material properties throughout the manufactured component. This capability is particularly valuable for complex geometries where thermal management challenges can lead to structural weaknesses or dimensional inaccuracies.

This technology democratizes advanced 3D printing by reducing the expertise required to achieve consistent results. Rather than relying on highly skilled operators to interpret process data and manually adjust parameters, the AI system autonomously optimizes manufacturing conditions based on real-time sensory input. This approach significantly improves first-time success rates while reducing the learning curve for new operators.

How to Utilize AI Features in EOS Systems

Step-by-Step Guide to Implementing AI in Manufacturing

Successfully implementing AI capabilities within EOS manufacturing systems requires a structured approach that ensures proper integration and maximizes return on investment. The process begins with a comprehensive assessment of existing data infrastructure, evaluating what sensor data, imaging information, and operational documentation is currently being captured and how it's organized. This foundational step is critical because AI algorithms require high-quality, well-structured data to deliver accurate insights.

Manufacturers should then identify specific operational challenges they aim to address through AI implementation. These objectives might include improving first-pass yield rates, reducing material consumption, minimizing equipment downtime, or enhancing product consistency. Clear objectives help determine which AI capabilities will provide the greatest value and guide the selection of appropriate algorithms and implementation strategies.

The third phase involves selecting the right AI tools for identified objectives. Anomaly detection typically employs time-series analysis algorithms, while image recognition requires convolutional neural networks, and knowledge management benefits from natural language processing. Companies exploring AI APIs and SDKs, EOS systems provide robust integration frameworks that facilitate connection with various AI platforms and services.

Training AI models represents the most resource-intensive phase of implementation. This process requires substantial historical data that has been properly labeled to indicate successful and unsuccessful manufacturing outcomes. The quality and comprehensiveness of this training data directly impacts the accuracy and reliability of the resulting AI models. Manufacturers should allocate sufficient time for this phase and implement processes for continuously expanding and refining their training datasets.

Deployment involves integrating trained AI models into operational EOS systems, which may involve edge computing devices for real-time analysis or cloud-based platforms for more complex processing. Finally, continuous monitoring and optimization ensure that AI models remain accurate as manufacturing conditions evolve and new materials or processes are introduced.

Pros and Cons

Advantages

- Enhanced process control through real-time parameter adjustment

- Significantly improved product quality and consistency

- Reduced equipment downtime via predictive maintenance

- Increased operational efficiency and throughput

- Data-driven decision-making based on comprehensive analytics

- Reduced material waste through optimized process parameters

- Democratized operation requiring less specialized expertise

Disadvantages

- Substantial initial investment in hardware and software

- Complex implementation requiring specialized expertise

- Data privacy and security concerns with cloud integration

- Dependence on high-quality training data for accuracy

- Potential workforce displacement through automation

Conclusion

The integration of artificial intelligence into EOS manufacturing systems represents a transformative advancement that elevates additive manufacturing from a prototyping technology to a full-scale production solution. Through sophisticated anomaly detection, advanced image recognition, and intelligent knowledge management, AI enables unprecedented levels of quality, efficiency, and reliability in manufacturing operations. As these technologies continue to evolve, they will further democratize advanced manufacturing capabilities while driving innovation across industrial sectors. Manufacturers who embrace these AI-enhanced systems position themselves to compete effectively in increasingly demanding markets where precision, speed, and adaptability determine commercial success.

Frequently Asked Questions

What sensor data is most valuable for anomaly detection in EOS systems?

Temperature, pressure, vibration, material flow rates, and laser power parameters provide the most valuable data for AI-driven anomaly detection in EOS manufacturing systems, enabling proactive maintenance and quality control.

How does AI improve image recognition accuracy in manufacturing?

AI enhances manufacturing image recognition through deep learning algorithms that identify subtle visual patterns humans might miss, enabling automated defect detection and real-time process monitoring with consistent precision.

Can AI knowledge management tools be customized for specific processes?

Yes, AI knowledge management systems can be trained on process-specific data, manuals, and documentation to provide tailored recommendations and insights for different manufacturing environments and requirements.

What are key requirements for successful AI implementation?

Successful AI implementation requires high-quality data, specialized expertise, clear objectives, robust infrastructure, and organizational commitment to continuous learning and optimization.

How do OT cameras and AI improve laser processing?

OT cameras capture wavelength emissions during printing, while AI algorithms analyze this data to make real-time laser parameter adjustments, ensuring consistent energy distribution and optimal manufacturing conditions.

Relevant AI & Tech Trends articles

Stay up-to-date with the latest insights, tools, and innovations shaping the future of AI and technology.

Grok AI: Free Unlimited Video Generation from Text & Images | 2024 Guide

Grok AI offers free unlimited video generation from text and images, making professional video creation accessible to everyone without editing skills.

Top 3 Free AI Coding Extensions for VS Code 2025 - Boost Productivity

Discover the best free AI coding agent extensions for Visual Studio Code in 2025, including Gemini Code Assist, Tabnine, and Cline, to enhance your

Grok 4 Fast Janitor AI Setup: Complete Unfiltered Roleplay Guide

Step-by-step guide to configuring Grok 4 Fast on Janitor AI for unrestricted roleplay, including API setup, privacy settings, and optimization tips